Overview

Machining and metalworking operations vary in how mist is formed, how much mist is generated, and size of the mist droplets to be captured. That’s why it’s important to choose a mist control solution that fits your specific needs. Mist collectors, when properly selected and applied, help maintain a cleaner work environment and reduce maintenance on process machinery in manufacturing facilities.

Donaldson is a global provider of filtration solutions for manufacturing industries. Our advanced technology, extensive portfolio of filtration products, and unrivaled customer support help manufacturers meet their clean air needs and reduce long-term costs of operation.

With more than 90,000 mist collectors installed, Donaldson Torit® has the expertise to provide a range of solutions for mist air quality, helping machining facilities maintain safe and efficient operations.

Wet Process Applications

Principle applications for Donaldson mist collectors include wet processes such as:

- Machining

- Turning

- Cutting

- Forming

- Grinding

- Quenching

- Asphalt production

- Rubber processing

Configurable, Built to Last, Higher Efficiency

Donaldson Torit mist collectors provide the optimal level of mist control for every operation with the industry’s highest level of build quality including:

- Water, smoke, or oil options with airflows from 100 CFM to 5,500+ CFM

- Durable motors and build quality

- UL-certified components

- Backed by our 10-year equipment warranty

Our broad range of advanced filter media improves performance, removes submicronic particles, and extends the life of your collector. And our competitive fit replacement mist collector filters give you Donaldson performance in a mist collector already in use.

Higher Quality Means Fewer Maintenance Headaches

Specifying for Optimal Efficiency

With so many variables in play, it can be difficult for a manufacturer to dial in the appropriate mist collection system. If a machining mist control system is not properly scaled and scoped, you will have an ongoing struggle on your hands. From break-downs to poor air quality to accidents and injuries, poor machine mist management can cause a host of health and production problems.

With global reach and a local touch, Donaldson offers a clear path to seamlessly integrate customized and reliable water, smoke, or oil mist management solutions into any machining process.

Mist Collection and Filtration Solutions

Donaldson mist collectors are available in a range of sizes from small individual machine collectors to large, centralized units, giving manufacturers more flexibility in creating a simplified solution with a lowest total cost of ownership. All models feature solid construction built to last and are fully customizable to fit your footprint.

Synteq XP™ Media Technology

Proprietary Synteq XP Media is engineered with a blend of small and large fibers with a resin-free bonding system. The small fibers are proven to increase filtration efficiency, while the larger fibers provide structural support and clear drain channels. The result is superior draining, resulting in lower pressure drop and longer filter life.

Syntec XP filters are among the 100,000 replacement filters and parts Donaldson has in stock and are ready to ship today.

Products

Resources

Articles

Videos

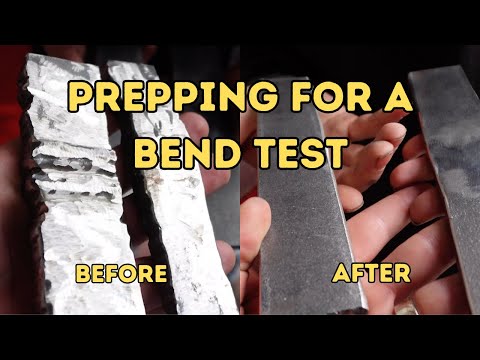

Welding Bend Test : How to prep your test coupons like a pro

Dive into the world of welding bend tests with Austin Hargett at Precision Welding Academy! In this video, watch as Austin guides a dedicated student through the art of preparing plate coupons for a bend test.