Overview

Welding generates gas and smoke containing various types of oxide particles. In addition to oxide particles, many processes also produce gases such as carbon dioxide and ozone. These gases can be hazardous if ventilation is inadequate.

Weld fume also contains additional small particles. The size of the particles can influence the toxicity of the fumes. Smaller particles present a greater danger, and exposure to metal oxides and gas byproducts is one of the leading hazards welders face. Whether you perform fusion welding that applies only heat (electric arc, gas or laser processes) or combine heat and pressure in your welding and cutting processes, the results are the same: All methods generate hazardous fumes.

Metal particles in weld fumes are 50 to 75 times smaller than the width of a human hair, making them extremely easy to inhale. Breathing metal particulates and gases is associated with a number of health effects, according to the Occupational Safety and Health Administration (OSHA) in its fact sheet on the issue.

Regulations

There’s no single guideline for weld fume exposure. Instead, OSHA enforces Permissible Exposure Limits (PELs) for specific metals, reflecting limits over specific periods of time. For example, for aluminum, iron, and mild steel, the PEL is 5 milligrams of particulates per cubic meter of air (5 mg/m3) averaged over an 8-hour period. Metals that are more toxic, including chrome, manganese, stainless steel, nickel, and cadmium, have stricter PELs.

Many welding operations strive to stay within Threshold Limit Values (TLVs) spelled out by the American Conference of Governmental Industrial Hygienists (ACGIH). These estimates of the exposure level a worker can tolerate over a career, are based on current scientific research and may be lower than PELs. A reference to PELs and TLVs is the Pocket Guide to Chemical Hazards published by the National Institute for Occupational Safety and Health (NIOSH). Be aware, however, that your operation may have additional state and local requirements.

Ventilation Recommendations

Ventilation is crucial for drawing fumes away from a welder’s breathing zone. OSHA makes these recommendations about natural and engineered ventilation:

- Stay upwind if welding in open spaces or outdoors, although this does not guarantee safety.

- Use local exhaust ventilation (also called fume extraction) for indoor welding.

- Never weld in confined spaces without ventilation.

- Where there is no mechanical ventilation, use natural drafts and position the work to avoid exposure.

In welding, laser, and plasma cutting applications, there are two common ventilation designs most seen in facilities. The two examples are:

- Source capture or enclosing hoods are the most effective in controlling contaminants. However, they can restrict access and force reconsideration of material and product handling. Another option is capturing hoods. They are less effective than enclosures but can be adequate if properly used.

- Ambient ventilation filters air in the entire room to reduce the airborne fume concentration. Consider this method only if source capture is not possible and/or practical. Because general ventilation does not remove fume at the source, it does not limit exposure at the worker’s breathing zone.

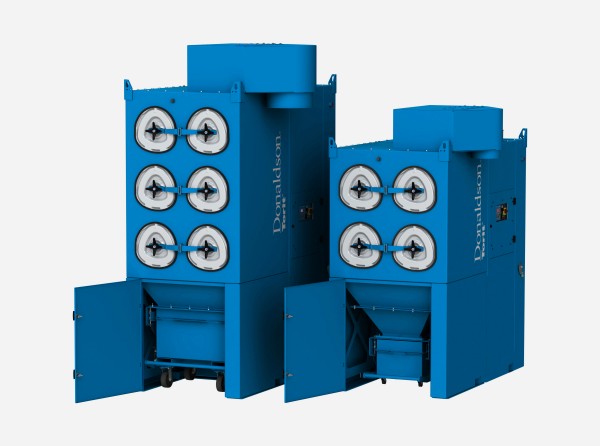

Donaldson can assist in designing the right ventilation system for your shop. We offer Torit dust & fume extractors and the PowerCore TG collector series that includes an ultra-highly efficient filter with a “smaller and smarter” footprint and the lowest maintenance cost in the industry.

Laser and Plasma Cutting

Thermal cutting applications, such as plasma and laser cutting, generate considerable levels of fumes and particulate that may present a health risk to operators and be detrimental to cutting machinery.

Frequently, integrated dust collectors in curing systems help reduce workers' exposure to fumes and help protects expensive machinery. When selecting and designing a dust collector, consideration of thermally generated dust should include filtration challenges due to particle size, loading and combustible dust risk.

Products

Applications

| Model | Product Family | Use | |

|---|---|---|---|

|

PowerCore TG-8 | PowerCore Dust Collector | Welding |

|

Downflo Oval (DFO) 3-12 | Cartridge Dust Collector | Plasma Cutting |

|

Downflo Oval (DFO) 2-4 | Cartridge Dust Collector | Welding (Source Capture) |

|

Downflo Oval (DFO) 3-3 w / Canopy Hood & Drop Curtains | Cartridge Dust Collector | Welding (Source Capture) |

|

Downflo Oval (DFO) 4-80 | Cartridge Dust Collector | Welding (Source Capture) |

Resources

Articles

Videos

From Weld.com: Avoid Toxic Welding Fumes - Bending - Demo - (13:22) Welding Bend Test: How to prep your test coupons like a pro

Welding fumes can be toxic so you want to make sure you are taking precautions. Using fume extraction like this Easy Trunk Collector from Donaldson can help keep those toxic fumes out of your lungs.

This video is used with permission from Weld.com. The views and opinions expressed in this video are those of the original creators and do not necessarily reflect the views and opinions of Donaldson.

Welding Bend Test : How to prep your test coupons like a pro

Dive into the world of welding bend tests with Austin Hargett at Precision Welding Academy! In this video, watch as Austin guides a dedicated student through the art of preparing plate coupons for a bend test.

Donaldson Torit Industrial Air Filtration - Exactly What You Need for Dust, Fume and Mist Collection

Donaldson Torit's broad range of collectors and filters gives the customers interviewed in this video exactly what they need for dust, fume and mist collection.