Overview

Mechanical cleaning may involve abrasive blasting, wire wheels, sandpaper/sanding belts, grinding wheels, or abrasive chips in tumbling mills.

To capture and entrain the large heavy particles produced by cleaning the required capture velocity is often very high with collection hoods positioned to direct materials towards the hood. Once captured, general practice recommends a minimum duct transport velocity of 1066 m/min / 3500 fpm (but 1219 m/min / 4000 fpm to 1524 m/min / 5000 fpm is often necessary). A hood that encloses as much of the operation as practical is generally desired. In situations where the material removed has toxicity concerns, complete enclosures may be necessary or workers may need to wear respirators in addition to using local exhaust ventilation.

Submarkets

Abrasive Blasting

Abrasive blasting or blast finishing, with all its variations, can provide enough power to remove heavy surface materials, or can be gentle enough to take print off paper without penetration. Typically, blasting provides one of three general – as a surface finishing, surface preparation, or surface modification process.

Foundry

Foundries continue to lead in this area today and Donaldson Torit® dust collectors provide the advanced filter technology required to do so. Donaldson Torit dust collectors are installed in hundreds of foundries worldwide exhausting furnaces of all types, mold making and break-out, pouring, casting, and finishing operations.

Metalworking

Mechanical surface cleaning for metalworking includes grinding, buffing and polishing processes that clean metal surfaces in preparation for painting, welding, or other operations. Metal surfaces in need of cleaning may be covered with paint, rust or oxidation; plated with other metals; or covered with molding sand, organics, or biological materials. Donaldson Torit dust collection equipment and filters are ideal for collecting dust and fumes produced from these types of metalworking processes.

Thermal Spray

Thermal Spray or Metalizing is a group of coating processes which deposits finely divided metallic or non-metallic materials in a molten or semi-molten condition on a surface/substrate to form a coating. The coating material may start out in the form of a powder, ceramic rod, wires, or even molten materials. The process has the potential to generate very small particulate often referred to as “fume”.

Welding

Welding generates gases and smoke containing various types of oxide particles. In addition to oxide particles, many processes also produce gasses such as carbon dioxide and ozone. These gases can be dangerous if ventilation is inadequate. There are multiple types of weld fume collectors, also known as weld fume extractors, that can be suitable for your process, as well as variations in welding applications to consider.

Wet Machining

Coolant mists, including water soluble or oil, when used in manufacturing processes often create droplets that can collect on surrounding surfaces. Mist collectors, when properly selected and applied, help reduce this situation, maintaining a cleaner work environment and reducing maintenance on process machinery as outlined in Donaldson’s Filtration Technology for Mist Industries. Workers do not have nuisance coolants, oils or lubricant mists in their work environment.

Videos

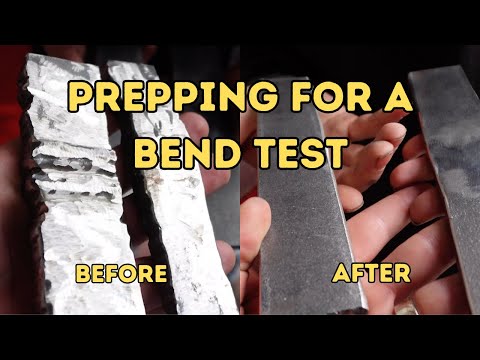

From Weld.com: Welding Bend Test : How to prep your test coupons like a pro.

Dive into the world of welding bend tests with Austin Hargett at Precision Welding Academy. In this video, watch as Austin guides a dedicated student through the art of preparing plate coupons for a bend test.

This video is used with permission from Weld.com. The views and opinions expressed in this video are those of the original creators and do not necessarily reflect the views and opinions of Donaldson.